NdFeB Magnetic Powder

Quenched NdFeB powder

Rapid quenched Nd-Fe-B permanent magnet alloy is one of the raw materials of bonded magnets. In recent years, the preparation of bonded NdFeB magnets extremely rapid development of technology and applications, the market is growing year by year. Quenched Nd-Fe-B alloy powder prepared is magnetically isotropic powder, the obtained bonded magnets is isotropic; each is hydrogen processing technology, also called the NdFeB powder prepared by the HDDR method anisotropic magnets prepared with this powder is anisotropic magnet.

The bonded magnet is a magnetic powder and a resin or polymer materials kneaded or magnetic particle cladding, and then with a molding method, injection molding method, extrusion method or rolling method, etc. will be prepared as the final size and shape, after curing sticky Results magnet. Because a certain amount of the binder is contained in the bonded magnet, these binders are non-magnetic material, and the density of the bonded magnet is lower than the sintered magnet, so its magnetic properties were lower than the sintered magnet. But bonded magnets have many advantages, excellent mechanical properties; without machining precision the final size of the product; cyclic products of the preparation of complex shapes and extremely thin; continuous volume automated production. Therefore in some areas, it is widely applied.

The quenched magnetic powder can also be obtained by hot pressing the original alloy density, high-density magnets, it is isotropic. Then by thermal deformation suppress such high density magnet to obtain an anisotropic magnet, this magnet and the sintering density of the magnet and the magnetic equivalent, but bonded magnet should not include these two magnets.

Property of NdFeB metal powder

| Property of NdFeB metal powder | |||||||||||

|

Grade |

Residual Induction Br(min-max) |

Coercive Force Hcb(min-max) |

Intrinsic Coercive Force Hcj(min-max) |

Energy Product (BH)max |

Density D |

Curie Temp TC |

Max Working Temp Tw |

||||

|

T |

KGs |

KA/m |

KOe |

KA/m |

KOe |

KJ/m3 |

MGOe |

g/cm3 |

℃ |

℃ |

|

|

A-11-13 |

0.74-0.80 |

7.0-8.0 |

464-512 |

5.5-6.5 |

960-1080 |

12.0-14.5 |

89-95 |

11.2-11.8 |

7.6 |

310 |

120-150 |

|

A-14-12 |

0.80-0.85 |

8.0-8.7 |

520-568 |

6.5-7.5 |

920-1000 |

11.5-12.5 |

110-116 |

13.5-14.5 |

7.62 |

310 |

120-150 |

|

B-8-7 |

0.73-0.77 |

7.0-8.0 |

320-400 |

4.0-5.0 |

560-640 |

7.0-8.5 |

66-70 |

8.3-8.7 |

7.6 |

305 |

100-120 |

|

B-10-8 |

0.73-0.80 |

7.3-8.0 |

360-440 |

4.5-5.5 |

600-680 |

7.0-8.5 |

80-85 |

10.0-10.6 |

7.6 |

305 |

100-120 |

|

B-11-8 |

0.76-0.80 |

7.5-8.0 |

400-480 |

5.0-6.0 |

600-680 |

7.5-8.5 |

88-93 |

11.0-11.6 |

7.6 |

305 |

100-120 |

|

B-12-9 |

0.77-0.81 |

7.7-8.2 |

440-520 |

5.5-6.5 |

640-720 |

7.8-8.8 |

96-101 |

12.0-12.6 |

7.6 |

305 |

100-120 |

|

B-13-8 |

0.80-0.85 |

8.0-8.5 |

456-536 |

5.5-6.5 |

640-680 |

7.8-8.6 |

102-105 |

12.8-13.2 |

7.6 |

305 |

100-120 |

|

B-13-9 |

0.79-0.84 |

7.9-8.4 |

456-536 |

5.7-6.7 |

680-760 |

8.5-9.5 |

102-105 |

12.8-13.2 |

7.6 |

305 |

100-120 |

|

B-14-9 |

0.81-0.86 |

8.1-8.6 |

480-560 |

5.8-6.8 |

680-760 |

8.5-9.5 |

112-116 |

13.8-14.4 |

7.62 |

305 |

100-120 |

|

B-14-10 |

0.81-0.86 |

8.1-8.6 |

480-560 |

5.8-6.8 |

760-840 |

9.5-10.5 |

112-116 |

13.8-14.4 |

7.62 |

305 |

100-120 |

|

B-15-7 |

0.86-0.93 |

8.5-9.5 |

440-480 |

5.5-6.5 |

560-640 |

7.0-8.0 |

120-124 |

14.8-15.4 |

7.62 |

325 |

100-120 |

|

B-15-9 |

0.83-0.90 |

8.3-9.0 |

520-600 |

6.0-7.0 |

720-800 |

8.5-10.5 |

120-124 |

14.8-15.4 |

7.64 |

350 |

100-120 |

|

ES-8-3 |

0.97-1.02 |

9.5-10.2 |

184-216 |

2.0-3.0 |

200-280 |

2.5-4.0 |

59-65 |

7.3-8.2 |

7.58 |

400 |

100-110 |

Property of φ10*10 sample magnet

|

Grade |

Residual Induction Br(min-max) |

Coercive Force Hcb(min-max) |

Intrinsic Coercive Force Hcj(min-max) |

Energy Product (BH)max |

Density D |

Curie Temp TC |

Max Working Temp Tw |

||||

|

T |

KGs |

KA/m |

KOe |

KA/m |

KOe |

KJ/m3 |

MGOe |

g/cm3 |

℃ |

℃ |

|

|

A-11-13 |

0.60-0.65 |

5.9-6.5 |

392-440 |

4.7-5.5 |

960-1080 |

12.0-14 |

58-62 |

7.3-7.8 |

7.6 |

310 |

120-150 |

|

A-14-12 |

0.64-0.68 |

6.3-6.8 |

440-488 |

5.4-6.0 |

920-1000 |

11.5-12.8 |

73-76 |

9.2-9.6 |

7.62 |

310 |

120-150 |

|

B-8-7 |

0.59-0.63 |

5.8-6.4 |

312-384 |

3.8-4.8 |

560-640 |

7.0-8.5 |

50-53 |

6.3-6.7 |

7.6 |

305 |

100-120 |

|

B-10-8 |

0.59-0.64 |

5.9-6.6 |

344-392 |

4.2-4.9 |

600-680 |

7.0-8.5 |

55-60 |

7.0-7.6 |

7.6 |

305 |

100-120 |

|

B-11-8 |

0.61-0.65 |

6.1-6.6 |

376-432 |

4.5-5.4 |

600-680 |

7.5-8.5 |

61-65 |

7.7-8.2 |

7.6 |

305 |

100-120 |

|

B-12-9 |

0.61-0.65 |

6.1-6.6 |

384-440 |

4.7-5.5 |

640-720 |

7.8-8.8 |

65-67 |

8.2-8.5 |

7.6 |

305 |

100-120 |

|

B-13-8 |

0.64-0.67 |

6.3-6.8 |

400-448 |

5.0-5.6 |

640-680 |

7.5-8.5 |

70-72 |

8.8-9.1 |

7.6 |

305 |

100-120 |

|

B-13-9 |

0.64-0.66 |

6.3-6.8 |

400-448 |

5.0-5.6 |

680-760 |

8.3-9.3 |

70-72 |

8.8-9.1 |

7.6 |

305 |

100-120 |

|

B-14-9 |

0.65-0.68 |

6.4-7.0 |

416-480 |

5.1-6.1 |

680-760 |

8.5-9.5 |

74-76 |

9.3-9.6 |

7.62 |

305 |

100-120 |

|

B-14-10 |

0.65-0.68 |

6.4-7.0 |

416-480 |

5.1-6.1 |

760-840 |

9.5-10.5 |

74-76 |

9.3-9.6 |

7.62 |

305 |

100-120 |

|

B-15-7 |

0.67-0.72 |

6.5-7.5 |

360-400 |

4.5-5.5 |

560-640 |

6.5-8.0 |

78-82 |

9.7-10.3 |

7.62 |

325 |

100-120 |

|

B-15-9 |

0.66-0.70 |

6.5-7.5 |

432-496 |

5.4-6.2 |

720-800 |

8.5-10.0 |

78-82 |

9.7-10.3 |

7.64 |

350 |

100-120 |

|

ES-8-3 |

0.81-0.86 |

7.5-8.5 |

192-232 |

2.4-4.4 |

200-280 |

2.5-4.0 |

50-56 |

6.3-7.3 |

7.58 |

400 |

100-110 |

Anisotropic NdFeB Magnetic Powder

New anisotropic bonded rare earth permanent magnet material, through special processing Nd2Fe14B anisotropic type magnetic powder, can be used for the preparation of the anisotropic injection and molded magnet. The particle size distribution and particle shape of the magnetic powder have been particularly designed and well adapted for bonding molded for high intrinsic magnet was prepared under the conditions of a magnetic field. (BH) max of the magnet prepared by the magnetic field injection molding method of up to 15 MGOe; magnets prepared by the molding method of the magnetic orientation, (BH) max reaches 25 MGOe, its magnetic properties are usually fast quenched NdFeB magnetic powder prepared in homosexual neodymium iron the boron bonded magnets more than twice. Anisotropic bonded magnets can be applied to a multi-polar micro-motor rotor, and magnetic tile sensors.

Technical parameter (Tested by VSM)

|

Parameter |

DXND-12P |

DXND-14P |

DXND-16P |

DXND-18P |

DXND-20P |

|

Br kGs |

13.5-14.2 |

13.5-14.0 |

13.0-14.0 |

12.5-13.5 |

12.0-13.0 |

|

bHc kOe |

8.8-9.2 |

9.0-10.0 |

10.0-10.5 |

10.3-10.7 |

10.6-10.7 |

|

jHc kOe |

11.0-13.0 |

13.0-15.0 |

15.0-17.0 |

17.0-19.0 |

19.0-21.0 |

|

(BH) MGOe |

36-40 |

38-42 |

36-40 |

36-40 |

32-36 |

Granularity Distribution of Magnetic powder

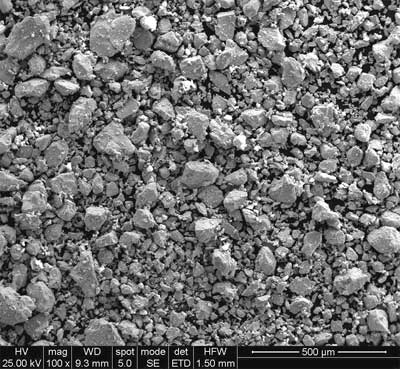

Magnetic particle morphology of electron microscope photos